Scrubber Tower Packing & Accessories

High efficiency plastic tower packings and accessories

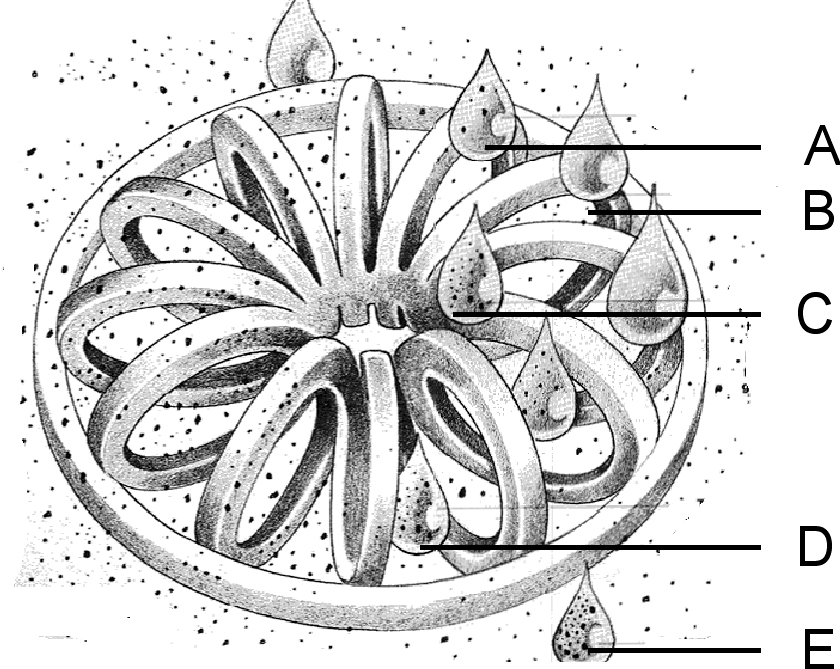

Tellerette® scrubber packings are a high efficiency plastic tower packing designed for use in wet scrubbers, cooling towers, mist eliminators, absorption columns and gas strippers.

They provide a surface area equal to many other packings but with much greater liquid surface availability. There are many times more interstitial hold up points than other packings, and this has the effect of continuously generating fresh liquid surface area which is the key for high mass transfer between the gas and liquid phases.

Tellerette® scrubber packings have a non-wetting surface, and are used in vessels with a diameter of more than 400mm; for smaller diameters use Tellerette® Type 1.

- Tellerette® Type 1 are used in small diameter towers.

- Tellerette® Type 2R are used in vessels with a diameter of more than 400mm. This packing is the original packing that has been used for more than 3 decades.

- Tellerette® Type 3K is the latest packing available in the range with improved mass transfer efficiency.

Uses

- Wet scrubbers for gas absorption

- Cooling towers for heat transfer

- Mist eliminators for liquid particle removal

- Gas absorption columns

- Gas strippers

- Air washers

Key Features & Benefits

Better Mass Transfer

Because of the shape with many interstitial points, liquid surface area is constantly regenerated, and this has been found to be more important to mass transfer than surface area alone. The design constantly renews the liquid surface at no additional cost in energy. This promotes high gas absorption efficiencies because of this natural agglomeration/dispersion cycle, a cycle that continuously exposes fresh liquid surface area to the gas flow.

Better Particulate Collection

The unique filamentous toroidal helix shape is designed to take advantage of inertial impact to collect solid and liquid particulates. Because the open, filamentous shape eliminates orifices where solids can drop out and accumulate, Tellerette® Type 2R packings are effective with high-solid particulate loadings. Tellerette® Type 2R packings are also effective mist eliminators following a wet scrubber.

Low Pressure Drop

The open filamentous shape of Tellerette® Type 2R packing minimises restrictions to the gas flow through

the packed bed thus minimising gas pressure drop and energy consumption.

Random Packed

Tellerette® Type 2R packing is placed in a vessel by random dumping thus minimising installation time.

No Liquid Redistributors Needed

Given proper initial liquid distribution such as with a full cone spray nozzle, the liquid is not channelled to the sides thus eliminating the need for liquid redistributors part way down a column.