An introduction to hangers and supports required when installing FRP duct. A reference table of maximum and recommended hanger/support spaces plus other information for engineers

What you need to know. Handling is easy due to the light weight of fibreglass. Avoid all point loads, and use nylon slings for lifting (not chains under any circumstances). Use lifting lugs provided.

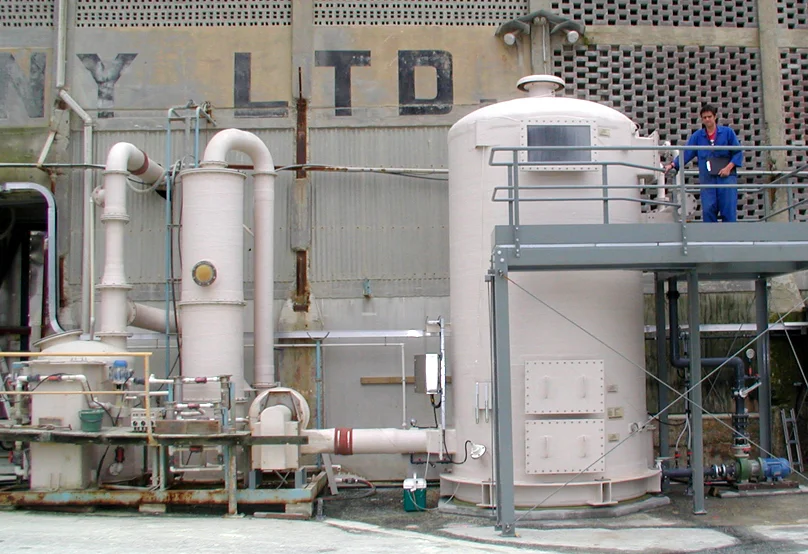

Corrosion resistant and light weight fibreglass ducting is widely used for ducting corrosive gases at industrial sites and in corrosive atmospheres.

Fibreglass pipes are considered to be 'flexible' pipes. They are designed to deform or deflect diametrically within specified limits without structural damage. The degree of side support provided by the backfill used is a major determinant of the pipe stiffness required.

Fibreglass laminates made by contact moulding, also called hand lay-up, have the highest resin to glass ratios of 70:30 when compared to alternative manufacturing methods.

A butt and strap joint is simple to do. The resulting joint is stronger than the pipe itself. Consult Armatec for full instructions and training. Use only Armatec approved materials.

Tellerette® Tower Packing is the first choice for many new absorption and scrubber applications and is an ideal replacement for existing extended surface packing, especially where greater throughput and/or efficiency is desired.

We have made Green Domes® Odour Filters simple and easy to install in any new or existing pumping station. Here we show you the instructions for installing yours.

As with any air pollution or odour control project, the four key steps that must be successfully undertaken are: collection, transfer, elimination and final dispersion. In New Zealand these steps must be considered in line with the ‘Air Discharge Consent’ for the site.

There are many considerations in deciding whether a biological scrubber is right for your application, and the successful implementation of that vision. The key design considerations to begin the journey include...

Biological Scrubbers (also called Bio-Trickling Filters) treat gaseous contaminants in an airstream by passing it through a bed of microorganisms that feed on the gaseous molecules, consuming the H2S and other compounds as food removing them from the airstream.

Life Cycle Cost (LCC) analysis is used to determine the most cost effective choice of scrubbing technology.